Bottle crusher EU patent

|

Model:

|

Loading:

|

Performance b/h:

|

|

CONTI

|

with infeed conveyor

|

up to 6000

|

|

SOLO

|

manually

|

up to 2400

|

• excellent crushing performance

• optimal volume reduction

• accident-proof (splinter protected)

• low noise [85/87 dB(Ai)]

• low wear rate

• compact design (minimum space requirement)

• optimal volume reduction

• accident-proof (splinter protected)

• low noise [85/87 dB(Ai)]

• low wear rate

• compact design (minimum space requirement)

Therefore, HEIN bottle crushers are a valuable addition

for the bottling operation.

for the bottling operation.

Model : CONTI

Fields of use:

• inspection machine

• presorting

• sorting

• sorting plants

• presorting

• sorting

• sorting plants

faulty bottles feed by means of belt conveyor

Application examples for

Model: CONTI

Loading: volume conveyor

Model: CONTI

Loading: volume conveyor

The model CONTI (automatic feed) is applied, if with high faulty bottles accrual (inspection machine, presorting, sorting) personnel and costs can be saved. In addition, the application of a CONTI line is recommendable, if for ergonomic reasons (insertion height) the application of a SOLO line is not recommended.

The bottle crushers can also be applied where waste glass is fed e.g. through funnels or slides to a container placed on a lower floor. The bottles are then directly fed into the pulverisation plant in bucketfuls through the funnel. In doing so, a crushing rate of up to 6000 b/h is achieved.

The bottle crushers can also be applied where waste glass is fed e.g. through funnels or slides to a container placed on a lower floor. The bottles are then directly fed into the pulverisation plant in bucketfuls through the funnel. In doing so, a crushing rate of up to 6000 b/h is achieved.

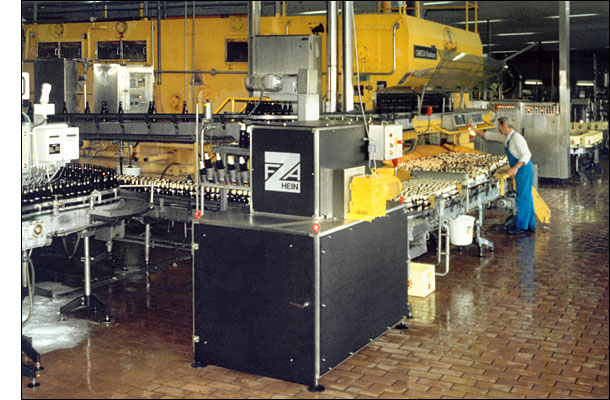

A group of bottle crushers with double-sided loading

in a sorting plant of a brewery

in a sorting plant of a brewery

Model: CONTI

-

infeed through belt conveyors

-

manual loading through the walkway-sided insertion ducts for the disposal of individual faulty bottles

rotation conveyor___

bottle crusher___

noise protection box w. shard bucket___

The decision as to which type of conveyor should be chosen for the faulty bottle movement, often depends on the

local space available.

Loading:

belt conveyor

rotation conveyor

lift station

conveyor

pusher etc.

rotation conveyors as feeder to the BCP

behind the sorting belt (area behind inspector)

behind the sorting belt (area behind inspector)

Model: CONTI

lift station___

bottle crusher___

noise protection box/shard bucket___

- with lift station (area: refeeding to the cleaning machine)

Model: CONTI

-feeding by rotation conveyor (Position: behind inspector)

Model: CONTI

Model: CONTI

-feeding by conveyor

Model: CONTI

shard discharge through the floor to the shard container

on the floor below

on the floor below

Model: SOLO

The inspection machine sends the faulty bottles through a sorting belt to a collection-table.

From here the bottle crusher (Model: SOLO) is manually loaded.

From here the bottle crusher (Model: SOLO) is manually loaded.

Application examples for

Model: SOLO

Loading: manually

Model: SOLO

Loading: manually

with a low faulty bottle rate (less then 1 %) manual disposal is economic

Model: SOLO

The sorting belt of the inspection machine feeds the bottles that are sorted out into the bottle crusher.

After a visual re-check the faulty bottle is manually fed into the BCP (Model: SOLO).

After a visual re-check the faulty bottle is manually fed into the BCP (Model: SOLO).